Turbo Actuators is used in many areas of manufacturing, […]

Turbo Actuators is used in many areas of manufacturing, including liquid penetrant repair. The technology is also very useful in the dental prosthetic industries. The product was developed by Turbo Actuators Ltd. based in the United Kingdom and has been available for sale in the United States since sometime in the mid-1990s. Because of its usefulness, the company has grown to become one of the world leaders in the design and manufacture of Turbo Actuators.

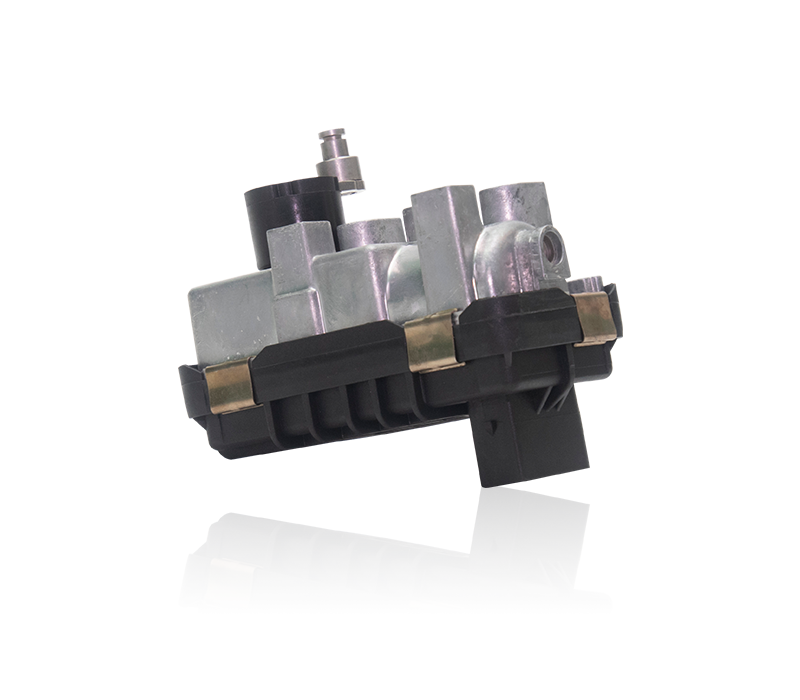

Turbo Actuators consists of a wastegate that creates a vacuum between an electric motor and a turbine. This causes the wastegate to close, thereby reducing the pressure and temperature of the incoming air. In some situations, such as with turbochargers, a pressure regulator or additional safety device is incorporated into the wastegate to keep the pressure at a safe level while the turbocharger is running. The resulting effect is a longer component life, greater efficiency, and less repair and maintenance costs.

As is the case with other electronic devices in the automobile industry, it is important to properly maintain turbochargers and turboactuators to ensure maximum performance and efficiency. Proper maintenance of these electronic devices allows them to operate at their peak, which increases the probability of preventing costly failures. These failures occur when an increase in temperature affects the proper operation of the electronic actuator. Since turboactuators use a small amount of fuel per cycle to increase combustion efficiency and reduce emissions, an increase in temperature can adversely affect the performance of this electronic device. It is for this reason that it is vital to service and repair these components on a regular basis.

Turbochargers and turboactuators are a key component in many industries, including the global turbo actuator market. The high-performance devices have a tremendous impact on the performance of an automobile. As with other components in the automobile industry, turboactuators require periodic service and repair to provide consumers with a cost-efficient, high quality product that can meet today's demands. Because of the significant cost involved with replacing these products, it is important for automotive manufacturers to maintain consistent high-performance levels of these items.

Automotive parts distributors and manufacturers offer a variety of solutions for the maintenance of turbo actuators and other parts. Some of these companies offer direct replacement, parts bin ordering, and parts manufacturing for Turbo Boost, Super Charger, Oil Change Springs, Turbochargerchargers, Oil Pan Inserts, Oil Filters, Oil Trimmers, and Turbo Sensor Clamps. Through these channels, the distributors and manufacturers can provide a wide range of products, including Turbo Actuator parts and systems. These products are backed by a heavy-duty 12V electrical system to provide continuous electrical flow to all of these components. Turbo actuator systems are available in single and multi-stage units, and the distributors and manufacturers offer solutions for both commercial and residential applications.

Turbo Boost is an aluminum case design with a multi-chambered steel tube that supplies the high-pressure air to the turbine, which is responsible for the fan-driven flow of the oil. Oil drain tanks are included for oil disposal purposes. Turbochargers increase the turbo actuator output by compressing the oil supply and increasing the oil temperature for even greater airflow. These turbo actuators and components work together to provide power and air acceleration for all engine applications.