The Turbo Actuator - A Competitive Edge For CNC Machini […]

The Turbo Actuator - A Competitive Edge For CNC Machining Technology

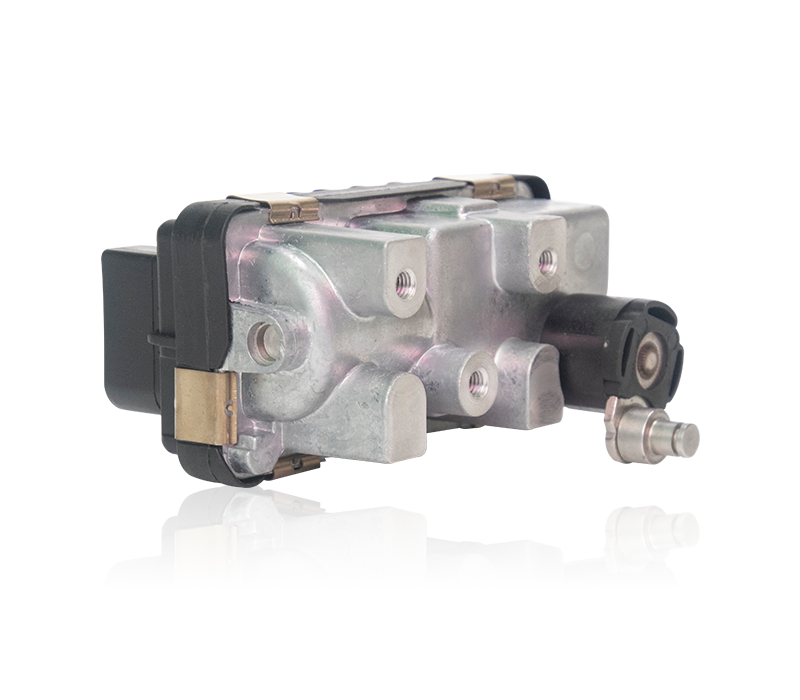

Pneumatic Turbo Actuators are the best solution to high pressure situations. Their unique design provides the user with maximum accuracy and flexibility. Pneumatic or "Pogro" is a highly efficient compressed air that makes the working environment safer for the worker and his/her equipment. In a traditional system the operator releases air from an inlet valve at the base of the actuator and pushes air into the housing through a discharge hose. Air is supplied to the actuator through the discharge hose, which requires a relatively large work area. Traditional systems require the operator to have access to the release hose and vent large amounts of air into the work area.

In addition to safety features, a Pneumatic Turbo Actuator is a cost effective solution for a variety of applications. The high efficiency and small footprint of a Pneumatic Turbo Actuator make them highly flexible and suitable for many high-volume CNC projects such as auto manufacture lines, sheet metal production and assembly lines, and stamping or die making machines. They are also suitable for use in the injection moulding industry, automotive, electronics, aerospace and medical industries. Because a Pneumatic Turbo Actuator does not rely on manual operation, the actuator can be used as a stand alone unit or can be used as part of a system such as a hydraulic turbo actuator or a rotary actuator.

The key benefit of a turbo actuator is its ability to increase boost pressure quickly. With an increase in boost pressure the actuator can produce more parts per cycle. In high volume CNC projects this could mean increased product output, less waste and higher speed with shorter run times. Turbo boost pressure increase also increases the available surface area of the actuator which allows for more efficient rotation of the turbine wheel.

Another important benefit to a Pneumatic Turbo Actuator is that it allows for automatic adjustments and constant monitoring. With a manual turbo report the operator would have to manually increase or decrease the turbo report while in a mechanical turbo system the increase or decrease in turbo pressure is controlled automatically. This allows for accurate adjustments during the production schedule and forecast period ensuring minimal errors.

With the increased competition in the CNC machining industry there has been a need to develop new and innovative solutions for the CNC industry. One such solution has been developed by European companies namely Masti and Wedgwood who have taken advantage of advances in the hydraulic turbo actuator market by developing an adaptable design. The ability to adjust speeds at different phases of the CNC process has proved to be a key competitive advantage. By adapting their designs to the different stages of the CNC process these companies have been able to design products that are more versatile than their competitors. These unique designs have allowed them to quickly capture a leading position in the lucrative turbo actuator market.

The importance of the CNC machining technologies has led to a significant rise in the popularity of products that incorporate these systems. As technology evolves, so do the benefits provided by the Pneumatic Turbo Actuators. The manufacturers and installers of these products have taken advantage of the competitive landscape created by these innovators and are providing high quality systems designed to match these specifications. By providing cost effective, reusable designs and easy to use, more efficient products that offer faster results has allowed companies to offer CNC software and robotic systems designed to meet the needs of the CNC industry.