When a turbocharger system fails, it's usually too late […]

When a turbocharger system fails, it's usually too late for a rebuild or another part to fix what's wrong. If your car had an accident and the turbocharger failed, you need to know what to do next in order to repair your car. If your car ran into a dirt road or a rock, what do you do? Rebuild or replace your turbo? Read this article and learn how to find out what to do first, what kind of vehicle you drive, and what parts you need to replace, rebuilding or repairing your turbo system.

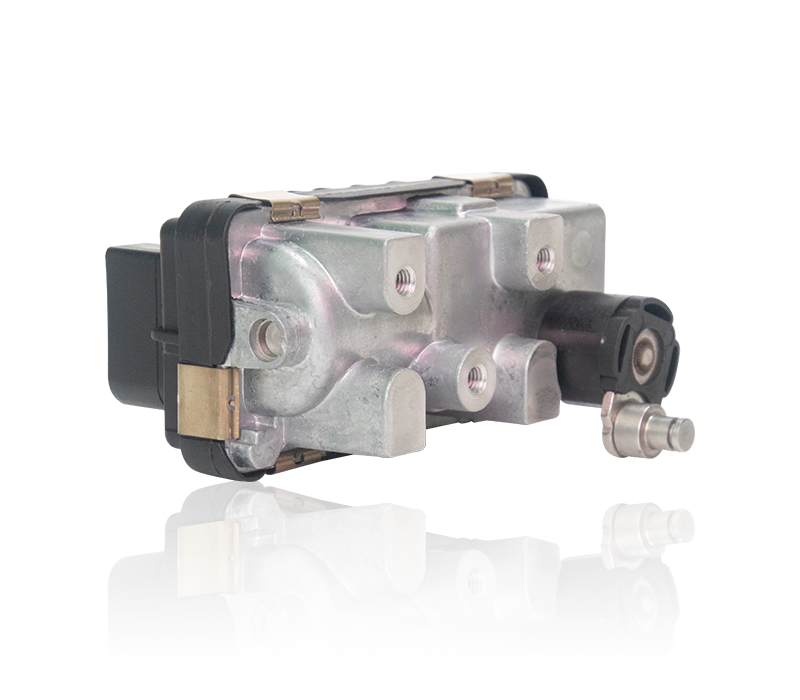

Before rebuilding or repairing your turbo system, you should identify the main cause of the failure. As part of most Turbo Manufacturers "No Repair Policy," if you were to discover a faulty Electronic Turbo Actuator sensor, you would need to replace both the turbo compressor and the turbo pressure sender/s, if applicable. Sometimes the sensor can be replaced with a universal unit that will detect the faulty position, and sometimes the actuators can be replaced separately. In addition, the manual usually provides some information on the different types of turbo compressors on the market, so you'll have an idea of which one you need.

Some electronic turbo actuators use hydraulic or adjustable vanes to maintain the turbo efficiency and minimize lift. In these cases, if the turbo actuator fails, all that needs to be done is to replace the hydraulic or adjustable vanes. A new batch of hydraulic vanes may be required, depending on the age of the hydraulic system. However, if your turbo compressor doesn't have adjustable vanes, you'll have to reinstall them, which can be more complicated.

For gasoline ECU conversion to work properly, the pressure and temperature of the fuel have to be detected correctly. This requires precise measurements and can only be accomplished by using digital scales and instruments called electric actuators. Electric actuators work by applying pressure to a piece of equipment's body in order to detect irregularities. If the variations are found, then either voltage or current is introduced to the circuit, depending on the required function. The problem can arise if the body of the electric actuator is too heavy, or the device's spring loads are too large. In most cases, however, the ECU will detect whether the electric actuator is not functioning as intended and automatically reset the process.

A second method used to detect problems with an ECU is to look at the output of the analog processor. If the processor sees a fault, then the ECU has no other option but to restart. For this reason, accurate diagnostics must always be run first before you plug in your turbo actuator to your engine. For most brands, this consists of inspecting the print circuit board for any etched lines, chips, or other voids. Then, your diagnostic technician will connect a small microchip relay to the output of the ECU, allowing it to send a defective signal back to the Hella digital control unit.

The next thing you need to check before plugging in your electronic turbo compressor into your vanes is the opening and closing vanes. This step only requires you to observe for any fluid leaks and clean out any clogs that appear on your filter. If you find these problems, most likely the problem is with the venturi valve. Vents are typically found on either side of the opening, but sometimes they can be found within the opening as well. This means that either the venturi or the mailbox may be dirty, causing a loss of horsepower and excessive pressure. However, with this step, you should also check the volume control valve and cylinder valve to confirm that everything is alright.

Finally, you should look for a printed circuit board. The ECU is connected to the rest of the electronic components through a printed circuit board, which monitors the operation of the entire system. If the circuit board has accumulated a crack in its surface, indicating that it has suffered a leak or other water damage, then you need to immediately replace your turbo actuator before it can further damage your engine.

Before plugging your electric motor into your newly installed, fuel-efficient turbo actuator, you must make sure that your electric motor is disconnected from the rest of the system. This is because the ECU and the rest of the components rely on the electric motor's position to regulate the flow of air, gas, and fuel throughout your vehicle. With this said, an existing leak will cause your actuator to fail in a matter of seconds, causing enormous strain on the engine. Check your engine several times a month, especially if you frequently travel long distances, to ensure that you won't have any leaks or damage your electric motor.